When you spill a drink, you don’t say, “Oh well, the only thing we can do is spill fewer drinks in the future.” You grab a towel. So there’s also a natural attraction to the idea that we should develop a towel that can remove CO2 from the atmosphere. That isn’t as simple as grabbing one from a Home Goods store, however, and cost estimates have not fueled optimism for most methods of doing this.

Reforestation is an obvious option, but its potential impact is probably smaller than you think. Other biological schemes could include growing biofuels to burn in power plants that capture emissions and store them underground. Recently, we’ve also seen a couple of working pilot projects that look like a power plant run in reverse—they suck in air and harvest concentrated CO2, ready for storage.

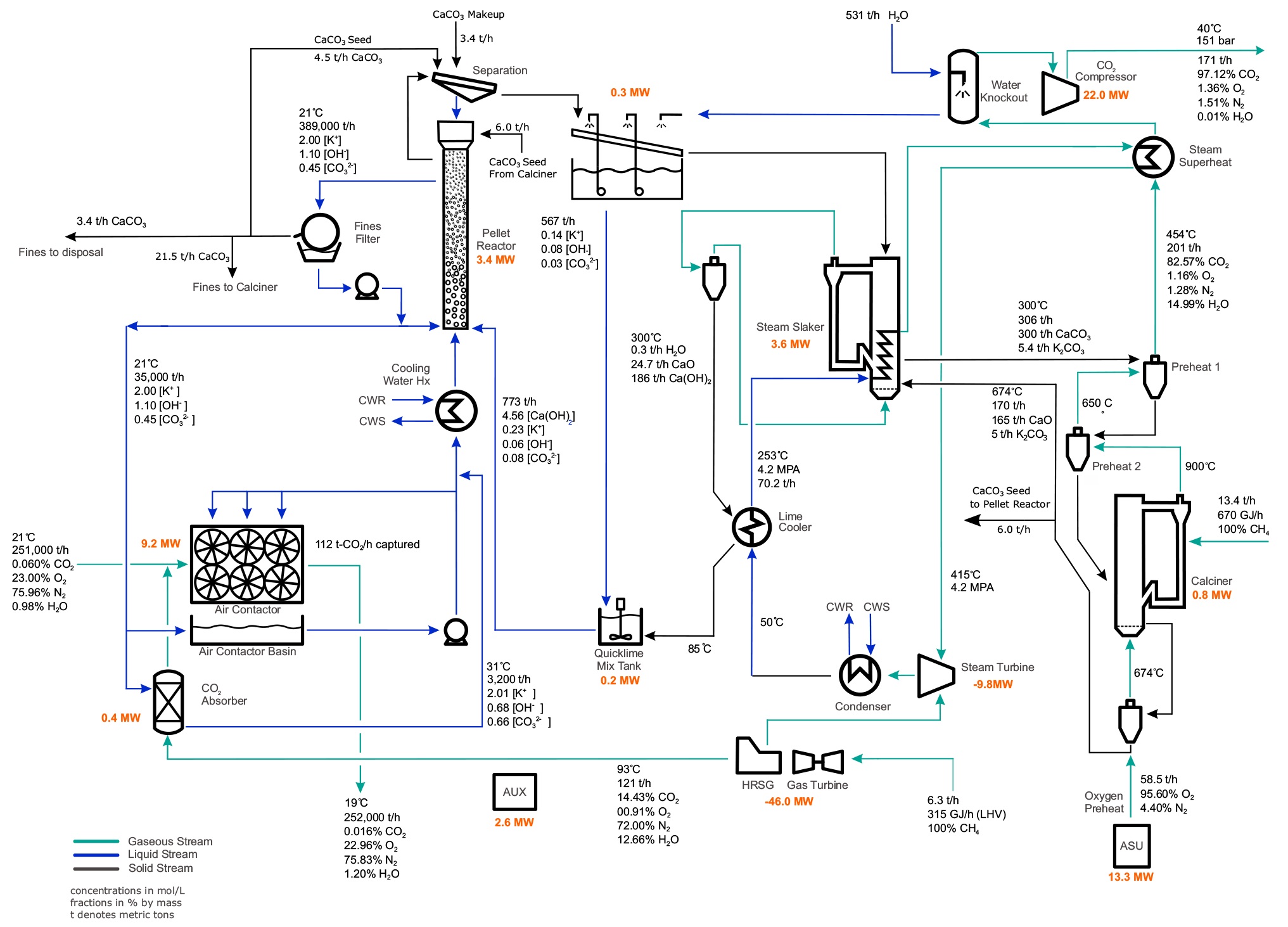

One of those plants, located an hour north of Vancouver, British Columbia, is the brainchild of a company called Carbon Engineering. One of the founders of Carbon Engineering is Harvard’s David Keith, a researcher studying this and other conceivable methods of “geoengineering” our planet’s climate. This week, the Carbon Engineering team has published a nuts-and-bolts breakdown of its design, providing the first cost analysis of a working carbon capture plant.

Carbon Engineering’s pilot plant and another pilot plant built by Climeworks in Switzerland diverge at the substance used to grab CO2 from the air. Climeworks opted for solid granules of amine, while Carbon Engineering is using a water-based solution of potassium hydroxide.

Cycling components

In their paper, the researchers explain their design choices. While their end task is obviously different, they were able to adapt existing machinery for each step in the process. By getting a little creative and optimizing components, they were able to bring the cost down significantly from previous estimates. All of this is laid out in great detail.

Loading comments...

Loading comments...